Home » Posts tagged '3d design consulting'

Tag Archives: 3d design consulting

The Advantages of 3D Printing

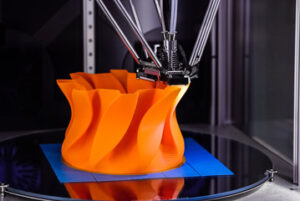

Phoenix 3D Printing transforms digital models into physical objects by layering material to form the desired shape. It was originally developed to accelerate the development of industrial products through rapid prototyping.

The process begins with a CAD model created in software. This model is then sliced into layers, which are then printed by the printer one at a time.

The rapid prototyping phase of product development allows teams to test out their concepts, make necessary changes and refine the design before putting it into production. This step is crucial for ensuring that the final product is functional, durable, and will resonate with end users. It also allows companies to avoid costly mistakes that can set back production time and costs.

One of the most popular forms of rapid prototyping is 3D printing. This process can produce complex geometry and details that cannot be made using traditional manufacturing methods. This type of prototyping provides nearly unlimited form freedom and eliminates the need for tools and molds, which are required with other manufacturing techniques.

The first step in the rapid prototyping process is to create a digital model of the desired object. This is done with computer-aided design (CAD) software. The CAD model is then converted into a file format that the printer can read, called a standard STL file.

Next, the file is sliced into hundreds of layers and prepared for printing by the printer. The layer thicknesses vary depending on the material used and the desired finish of the prototype. For example, thin layers of PLA filament are appropriate for visualization prototypes, while thicker layers of photopolymer resin or sintered nylon are ideal for functional prototypes that can be tested in the field.

Once the printed prototype is finished, it can be inspected by engineers for flaws and taken to market testers to see how well the prototype performs in real-world conditions. If the feedback is positive, the company can then move forward with the finalized design.

For many industrial manufacturers, rapid prototyping is a critical component of the product development process. This technology allows them to shorten the product design and development cycle, reduce their risk and improve their overall competitive advantage.

For example, MotoCilino is an engineering services firm that utilizes the Nexa3D XiP desktop 3D printer to rapidly prototype their hardware products for the automotive, biomedical and consumer electronics industries. This helps them churn out new innovations and improve their existing product lines, and cut down on time to market by up to 85%.

Rapid Manufacturing

Whether used to produce a proof of concept, or as a tool to guide products through a series of validation stages toward mass production, 3D printing is an ideal choice for prototyping. Unlike traditional manufacturing methods, it allows companies to go from CAD design to holding the prototype in hand in days rather than months. It is also possible to make many iterations of a product to quickly evaluate different sizes, shapes and assembly options.

With this rapid prototyping, it is easier to make changes in a product’s shape and assembly as necessary and reduce the risk of costly mistakes during mass production. Moreover, with digital design validation and verification, potential errors can be identified and corrected early in the process, which minimizes defects and enables more efficient production.

The type of 3D printing technology chosen depends on various factors, including the complexity of the product and material requirements. Sintering technologies (such as direct metal laser sintering and selective laser sintering) use heat to melt and fuse materials together while stereolithography uses photopolymerization to cure and solidify a cross section of the printed part in thin layers. These technologies are ideal for producing functional prototypes where the functionality of the product is more important than its visual appearance.

Some applications for 3D printing include making jigs and fixtures, spare parts and end-use components for the automotive, electronics, medical, aerospace and aviation industries. For example, Australian company Quad Lock has used 3D printers to develop vibration-dampening smartphone mounts for motorcycles that allow users to connect their devices securely while on the move. The company was able to create multiple iterations of the model using 3D printing, testing each prototype for its strength and usability before moving on to the next iteration.

Another use of 3D printing for rapid manufacturing is to create low-run injection molds. This process can be much more cost effective than creating molds through traditional methods, reducing the overall cost of the final product. It is also a great option for producing customized products, such as medical devices that are molded to an individual’s anatomy.

Personalized Content

With 3D printing, consumers can choose from a wider range of product designs and customizations. Unlike traditional mass production methods that use standardized molds, 3D printers allow manufacturers to fine-tune products for specific end-user needs such as ergonomic fit and performance optimization. This level of personalization can make a huge difference to consumers, who often expect products and services that feel tailored to them.

As a manufacturing method, 3D printing also reduces production costs, with 46% of respondents to a recent Jabil survey stating that this technology saves on everything from capital purchases and tooling to labor and overhead expenses. This is largely because of the fact that 3D printing eliminates the need for a physical assembly line, cutting down on time and labor costs. It’s also a much more flexible process, with the ability to produce multiple iterations of a product at once, and even shift production into traditionally costly nights or weekend shifts.

Another way 3D printing cuts costs is by allowing manufacturers to print parts that would be difficult or impossible to create using other means. This is especially true in the case of metals, where the capabilities of the technology open up entirely new possibilities. For example, cold metal fusion — which combines established powder metallurgy processes with high-powered lasers — can produce stainless steel and titanium parts. This has opened up the possibility of printed medical equipment, including patient-specific prosthetics and surgical tools.

Beyond this, the democratization of 3D printing has made it easy for anyone to use and fabricate their own customized digital design models. Online repositories, like Thingiverse, allow individuals to upload their own designs that can be downloaded and printed with a home 3D printer.

As a result, the personalization of products with 3D printing is growing in popularity. Food and dietary supplements producers are now able to add functional ingredients that can benefit the health of their consumers, with a focus on alleviating nutritional deficiencies and metabolic disorders. This approach, known as personalized nutrition, can also help reduce waste and reduce the burden on natural resources.

Sustainability

3D printing has a number of sustainability advantages that can help to improve efficiency and reduce the environmental impact of building and manufacturing processes. Its additive process adds layers of material until an object is complete, which contrasts with traditional subtractive manufacturing processes like molding and machining. This method also creates less waste material than conventional processes, and can even use recycled materials for some prints. Some manufacturers also offer environmentally friendly printer filaments, including plant-based and biodegradable materials.

In addition, 3D printing can be used to make spare parts for equipment, which is a great benefit for disaster preparedness. It can help to speed up the repair of critical infrastructure like water pipes, power lines, and buildings after an earthquake or other natural disaster. For example, tech-based NGO Field Ready 3D-printed water pipe fittings and washers on the spot in Nepal following a 2015 earthquake. This technology can also be used to print replacement parts for medical equipment, such as syringes or surgical tools.

Using 3D printing to make parts on-site is also sustainable, as it eliminates the need for shipping across long distances. This can cut down on the energy and emissions associated with transporting large, heavy materials utilized by the construction industry. Additionally, it can lower costs and provide greater flexibility for businesses to produce their own products on demand.

Many companies are utilizing 3D printing for greener initiatives, such as creating custom-made prosthetics and implants, which helps to ensure the best fit and function. This approach can increase patient satisfaction and lead to better outcomes after surgery. 3D printing is also being used to create detailed medical models, which can be used for training and research purposes. This will help medical professionals to prepare for more complex procedures and surgeries.

The sustainability of 3D printing is also impacted by the material used for prints, as well as how and where it’s produced. To be truly sustainable, the materials used to make an item must be sourced from renewable resources, and should be made of recyclable or biodegradable materials. In addition, the printed materials should be disposed of or recycled in an environmentally responsible manner. This will help to close the loop and contribute to a circular economy, which is an economic model that focuses on keeping products, materials, and resources in continuous use rather than discarding them after they’ve been used once or twice.